top

Micrinizer mill workflow and graphical analysis

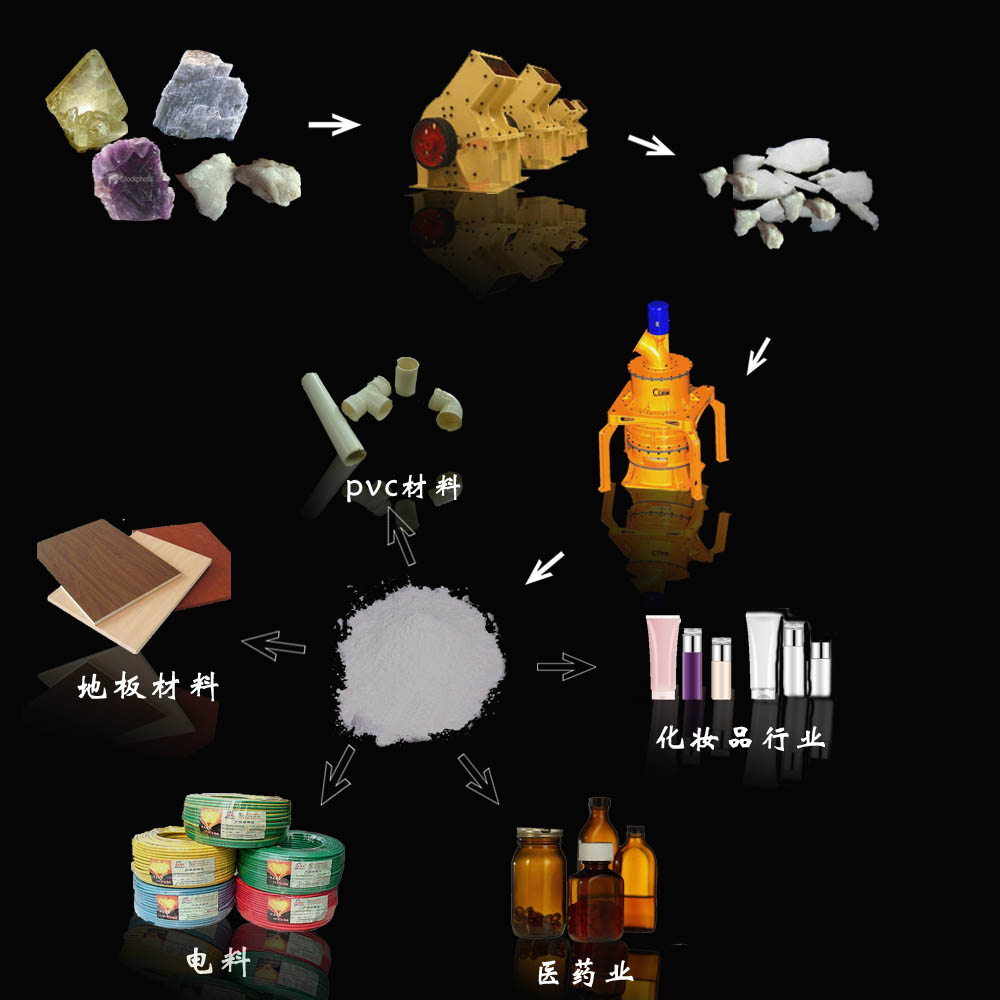

Everyone knows micronizer mill equipment is actually large pieces of material into very fine flour powder, then powder can be applied into many areas, this process is how to be processed and then apply it ,Clirik machine Co. will tell you the kind of application.

Chunks of material generally can not be added directly to the micronizer mill for grinding, if the material is large, then the general crusher equipment buy a first crushing large pieces of material, broken into small pieces and then added to the micronizer mill after lapping, grinding into fine powder can be adjusted between three hundred head to head 3000, and Clirik professional packaging machine, the powder can be directly packed into bags and then in various fields application, look at the following diagram day operations processes and applications.

HGM series micronizer mill mainly consist of main unit, classifier, powder collector, dust cleaner, blower, muffler, sound-proof room, crusher, bucket elevator, storage hopper, and vibrating feeder.

After crushed by hammer crusher, the large materials become small ones and are sent to storage hopper by elevator, and then evenly sent to the upper distribution plate of the turn plate by vibrating feeder and sloping feeding pipe.

When the grinding mill is at work, the main bearing and each dial are driven by electromotor of main equipment through reducer, and all the grinding rollers are rolling in the ring channels driving by dial through plunger. The materials are driven to the edge of the turn plate by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed, crushed and grinded by the rollers. Then the materials fall into multiple layers and to be crushed and ground continuously to micro powder.